Brakes

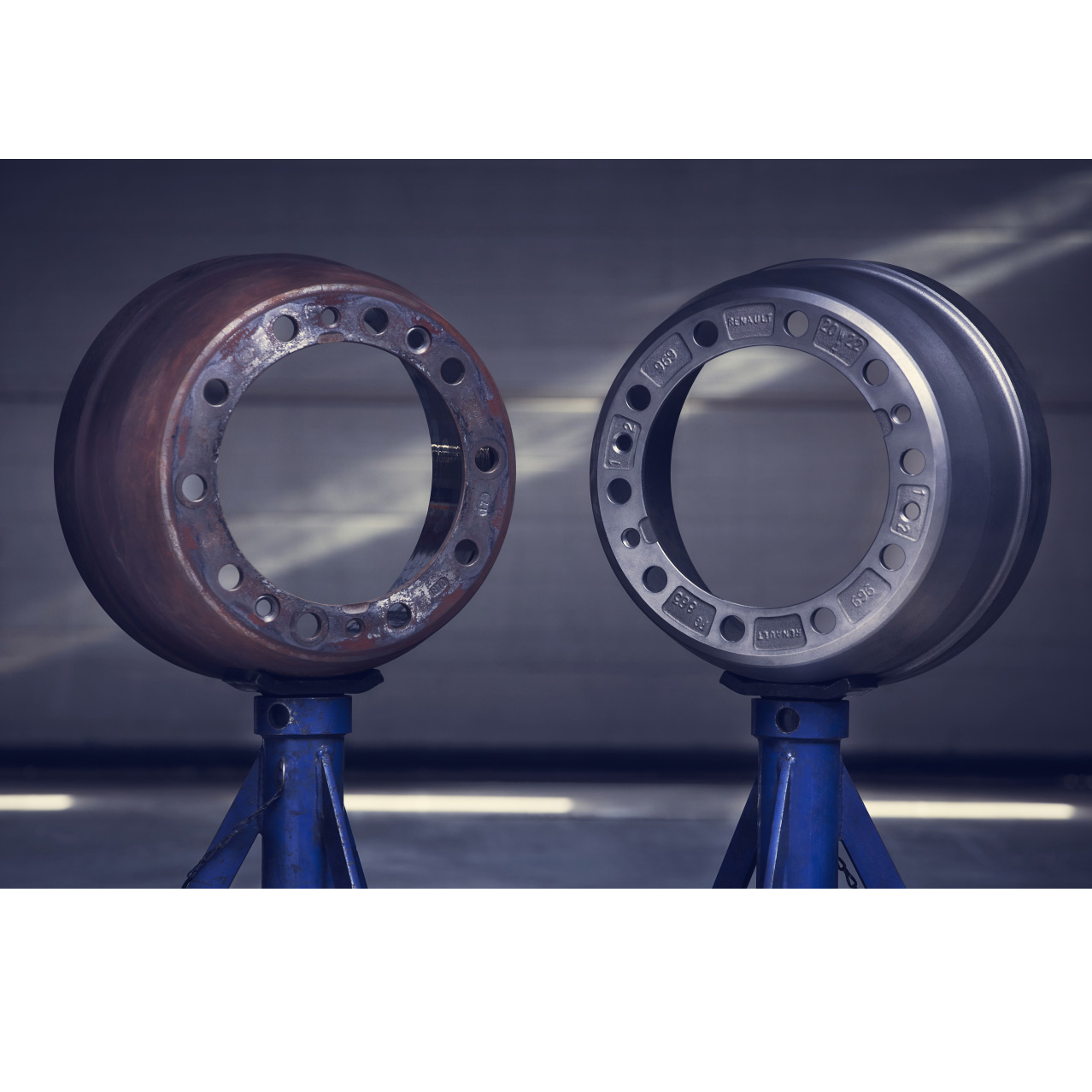

Brake linings and drums

Renault Trucks offer

Key arguments

Medias

FAQ

I don't want to buy original Renault Trucks parts because they are too expensive when compared with adaptable parts.

Renault Trucks brake linings and drums were developed together. This ensures all parts share common characteristics based on the same designs with optimised friction materials.

By purchasing an adaptable part, you run the risk of having an item with different frictional characteristics:

- insufficiently resilient equipment is liable to result in premature wear of the linings;

- excessively resilient equipment will wear out the brake drum prematurely.

In both such cases, costs will be higher because the parts will have to be changed more frequently.